Filament Storage

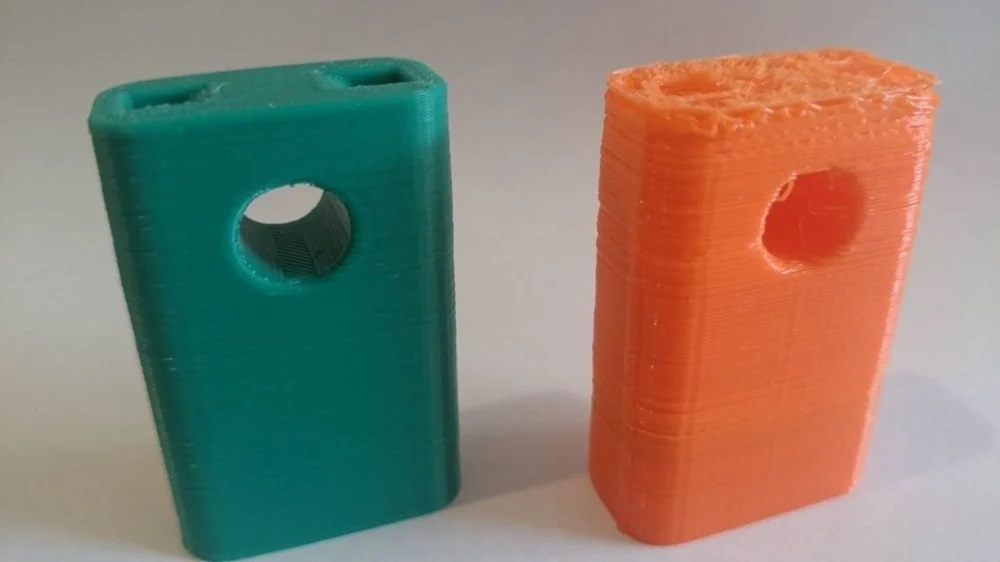

The orange filament wasn't dry before printing

Filaments tend to lose their quality when exposed to moisture, so our next tip is to try changing or drying your filament. Once a filament absorbs moisture, the material degrades and, as a result, is more difficult to print and issues like layer delamination are more prone to occur.

More hygroscopic materials, like ABS, PA, PC, PETG, PVA, TPU, Many Flexibles materials, will undergo this process faster than others. If you’re using something particularly hygroscopic or see evidence that your filament is wet (based on the texture of your prints), you may want to try a print with a different spool of filament before moving on to the the final tip.

Although there are no completely non-hygroscopic materials, there are some that are less prone to hygroscopic issues. The following materials are less vulnerable to absorbing moisture than those above: ASA, PLA, PP.

Using a dry filament can help prevent layer delamination and other quality issues in prints, and you can do this by either using a new spool or drying your current one. Once you dry your filament, to keep it in good condition, we recommend storing it in an air-tight container / back with a bage of Desiccants to prevent moisture from getting in.

Drying Filament

You’ve done the tests, and your filament is wet. Time to dry it.

In fact, drying filament is easy. Simple put the spool in the oven  and set the temperature to around 40-60 degrees Celsius (approximately 100-130 degrees Fahrenheit). Then, leave it there for around 4-6 hours. Or use an filament dryer like this: Filament Dryer

and set the temperature to around 40-60 degrees Celsius (approximately 100-130 degrees Fahrenheit). Then, leave it there for around 4-6 hours. Or use an filament dryer like this: Filament Dryer

For even more and better filament drying, you can put desiccants in the oven with the filament too. Printing with your filament from a dry box is also a good idea for the constant prevention of hygroscopy-related errors.